Check with shop staff for safety instructions if aluminum must be ground. Abrasive wheel machinery should not be operated without the appropriate guards in place.

Safety Inspection Checklist Abrasive Wheel Grinders Bench And Pedestal Pdf

91-11-28117865 91-11-30583633 fax.

. They offer protection in case of wheel failure and protects hands and fingers from injury. The amount of material removed from the work is very less. Assure work rests eye shields and wheel tongue and spindle guards are in place and secured.

Rough grinding machines 2. Tongue guard For buffing or wire-wheel applications. Enter NA Is tongue guard in place.

ENDING OPERATIONS AND CLEANING UP Switch off the machine when work completed. Aluminum dust is explosive. Inspect the pedestal or bench grinder for damage or disrepair.

Prior to powering up the grinder place the desired wheelbuff mop onto the machine spindles. Note that if the bore sizes on the grinding wheels andor buffering mops do not fit the spindle taper adapters and buff adapters are. Let the wheels gain maximum speed before starting to grind.

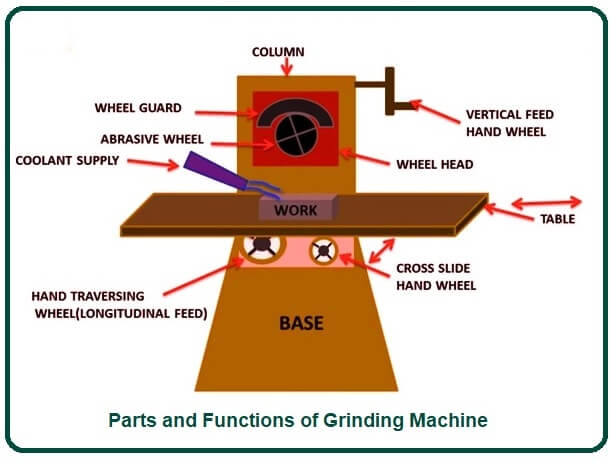

The base made of cast iron may rest on a bench pedestal or floor depending upon the design. POTENTIAL HAZARDS AND INJURIES. Wheel is mounted on a grinding machine.

B - 73 phase - 1 mayapuri industrial area behind police station new delhi - 110 064 india mobile. Is the grinding machine secured to the bench or pedestal in a manner that prevents it from vibrating moving during use. The accuracy of grinding process is 0000025mm.

Slowly move the workpiece across the face of the wheel in a uniform manner. Review and understand information provided in the pedestal or bench grinder operators manual with particular attention given to descriptions of safety procedures. Pedestal Grinder Purpose Grinders are very helpful for removing the last layers of excess material especially ferrous and other harder metal workpieces.

Grinding and Abrasive Machines 111. A coated abrasive belt runs over two pulleys - one driving pulley and one idler pulley. The grinder itself is a relatively small but powerful 1-2 HP motor.

Use vice grips to prevent burns. Is the power cord including plug free of breaks andor other damage. PedestalBench Grinder Safety Evaluation Checklist.

When installing a new grinding wheel fol lowing a ring test or when removing a wheel to be tested Lock OutTag Out LOTO procedures must be employed. Excess metal present on the cast parts and welded joints are removed by rough grinders. Larger and heavy duty machines are grounded on the floor.

The machine on which grinding the operation is performed is called a grinding machine. Do not use wheels that are chipped or cracked. Make sure all the guards are in place 2.

Safety glasses face shield hearing protection proper. RESULT Performing operation on more than one Job at a time. The tool rest on a bench grinder should be.

Cracked or defective grinding wheels can explode when in use. Grinding is done to obtain very high dimensional accuracy and better appearance. If material gets hot allow it to cool.

Belt Grinding Machines may be broadly classified according to the backups used as 1Platen Grinding Machines 2Contact Wheel Grinding Machines 3Free belt grinding machines 4Centreless grinding machines In construction all the machines are similar. Store grinding wheels carefully on racks in dry places and visually inspect them for warping chips cracks or other damage before installation. Is guard free from cracks and in good condition.

Precision grinding machines 421 Rough grinding machines The rough grinding machines are used to remove stock with no reference to the accuracy of results. Grind down to desired shape or smoothness. Pedestal and Bench Grinder.

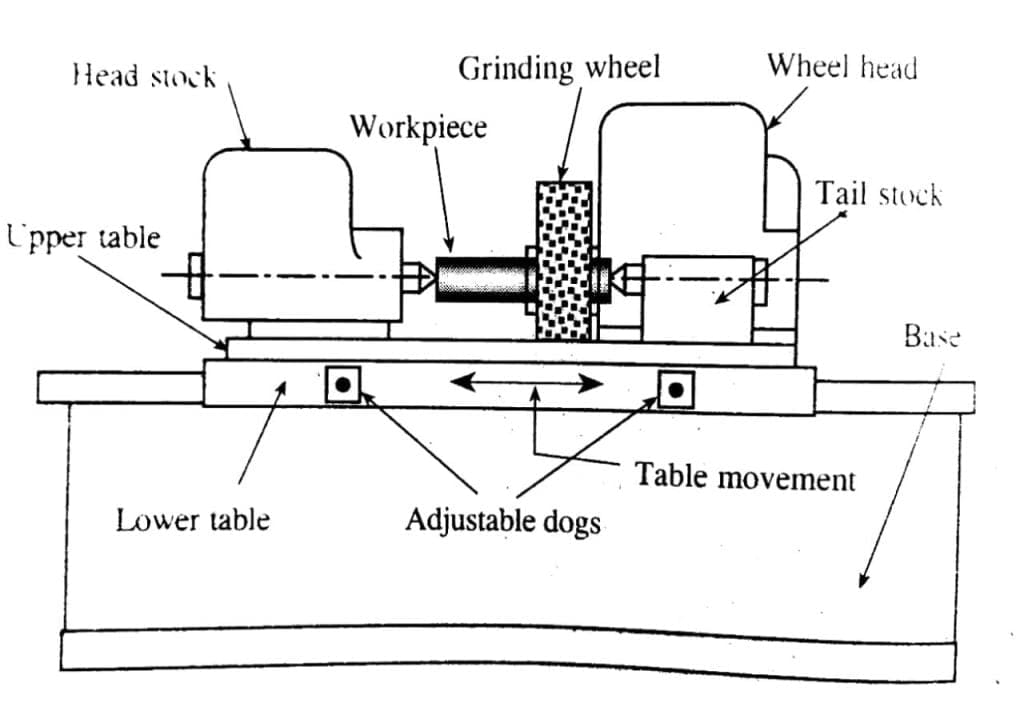

They are used on the periphery only and therefore produce a slightly concave surface hollow ground on the part. Work rests or tools rests are provided on all machines. Work between centers 1112.

Also drill bits and other lathe and milling tools can be sharpened fashioned and modified with the use of a grinder. Is distance from wheel 14 of an inch. In addition adjustable guards must be properly secured before use.

Bench or Pedestal Grinder Safety Do not grind aluminum. The floor- mounted utility grinding machine shown in Figure 5-1 mounts two 12-inch-diameter by 2-inch-wide grinding abrasive wheels. It is accurately machined and the table can be moved up and down.

Only use the tool when it is secured to the floor via a pedestal or work bench. Always stay at the machine while it is running. Inspect the wheels before turning on the power.

And can be found on bench or pedestal grinders. Rest your part on tool rest and lightly touch it against the wheel 4. Always check that a Grinding Wheel RPM Rating is consistent with speed of the Grinding Machine.

Hand grinding machine 2. Floor Mounted Utility Grinding Machine The typical floor-mounted utility grinding machine stands waist-high and is secured to the floor by bolts. Bench and Pedestal Grinders The grinder should be positioned by height and location to eliminate the need to overreach while grinding.

The column is mounted vertically upon the base. Is the grinder operator provided with and using proper personal protective equipment eg. The transmission cover and outer wheel guard must be secured in the proper position prior to operation.

The basic parts of a drilling machine are a base column drillhead and spindle. Leave the machine in a safe clean and tidy state. Raise the pedestal grinder slide the pallet away from the machine and re-lower the grinder to the final location.

Crankshaft and other special applications. Never remove guards from a BenchPedestal Grinder. Secure both pedestal and bench style grinders securely to the floor or work bench to prevent movement during usage.

Turn on the machine by flipping toggle switch to on 3. The main types of rough grinders are. 21 Types of grinding machines According to the accuracy of the work to.

Turn off the machine by flipping the toggle switch to off. Clean up and absorb any coolant spills immediately. Look for chips cracks or embedded metals Ensure tool rests are not more than 2mm away from grinding wheels - Avoid pinch points Ensure cooling dish has ample water in it Cool parts often Ensure appropriate guarding is in place Identify ONOFF switch Inspect General condition of working area Title.

Pedestral Grinder Mg10 12 Pedestral Grinder

Parts And Functions Of Grinding Machine Grinding Machine Grinding Machine Types

17 Types Of Grinding Machine Their Uses Grinding Defects

Pedestal Grinder Objectives 1 Identify The Major Parts Of A Pedestal Grinder With 80 Accuracy 2 Identify Appropriate Use Of A Pedestal Grinder And Its Ppt Download

Parts And Functions Of Grinding Machine Grinding Machine Grinding Machine Types

14 Types Of Grinding Machines Working Diagram Pdf

Grinding Machine Definition Parts Working Principle Operation Advantages Application Notes Pdf

18 Inch Power Touch Heavy Duty Pedestal Grinding Machine 5 0 Kw Rs 85000 Id 23337315073

Ds 200 619200000 Bench Grinder Metabo Power Tools

Dsd 250 619250000 Bench Grinder Metabo Power Tools

Bench And Pedestal Grinder Onguard Safety Training

Dsd 250 619250000 Bench Grinder Metabo Power Tools

14 Types Of Grinding Machines Working Diagram Pdf

Pdf Cnc Harish Avunoori Academia Edu

Pedestal Grinder 3hp Three Phase Bench Grinder Manufacturer From Rajkot

Brierley Double Ended Grinders Chester Machine Tools

China Electric Pedestal Grinder M3020 M3025 M3030 M3035 M3040 Pedestal Grinding Machine China Dust Sucking Grinder Bench Grinder

14 Types Of Grinding Machines Working Diagram Pdf